The Innovative Company

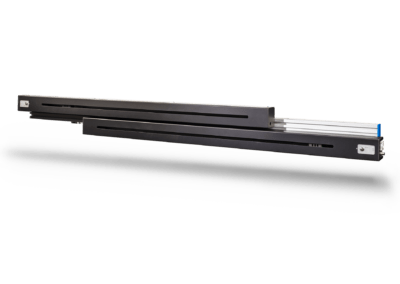

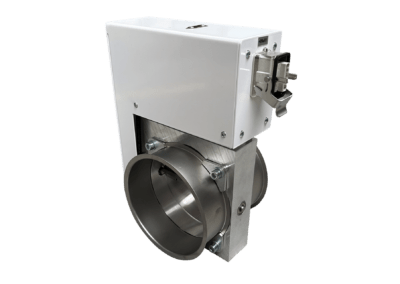

Steigern Sie die Performance Ihrer Blasfolienanlage mit Produkten von Kdesign.

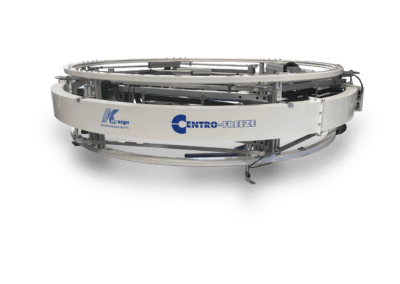

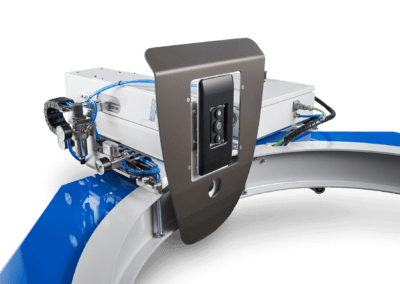

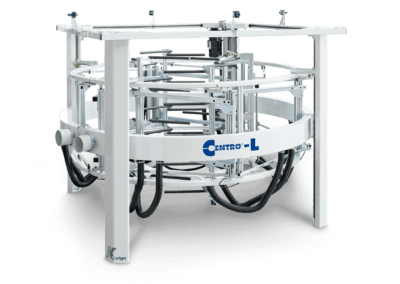

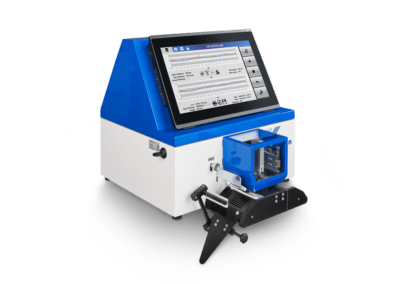

Kdesign bietet marktführende Technologien aus den Bereichen Kühlung, Messung und Kalibrierung.

Unsere Produkte

Warum Kdesign

Mit Kdesign entscheiden Sie sich für marktführende Technologie und höchste Performance für Ihre Blasfolienanlage. Profitieren Sie dabei von unserer Expertise aus über 20 Jahren Erfahrung in der Nachrüstungen von Bestandsanlagen sowie der Ausstattung von Neuanlagen namhafter europäischer und internationaler Blasfolienanlagenanbieter.

Kdesign steht für maßgeschneiderte und wegweisende Lösungen aus den Bereichen Kühlen, Messen und Kalibrieren.

Exzellenter Service von Kdesign

Durch die Vermeidung ungeplanter Down Time steigern Sie die Wirtschaftlichkeit Ihrer Anlage und erhöhen die Termintreue zum Kunden. Daher hält Kdesign ein Team aus erfahrenen Servicetechnikern bereit, um Sie präventiv zu beraten und Ihnen im Ernstfall zügig und kompetent zur Seite zu stehen.

Über Kdesign

Als Innovationsführer entwickeln, produzieren und vertreiben wir die Blasfolientechnologie der Zukunft. Kdesign bietet Ihnen daher ein interessantes Tägigkeitsfeld mit kurzen Entscheidungswegen und Aufstiegsmöglichkeiten. Dabei profitieren Sie gleichzeitig von der Stabilität und Zukunftssicherheit der Reifenhäuser Gruppe, der Kdesign angehört.

Unsere offenen Stellen finden Sie im Karriereportal der Reifenhäuser-Gruppe.

Kontaktmöglichkeiten

Beratung

Falls Sie Beratung wünschen, können Sie uns gerne telefonisch oder per E-Mail kontaktieren. Wir unterstützen Sie gerne.

Support

Falls Sie Unterstützung oder Hilfe benötigen, kontaktieren Sie bitte den Service von Kdesign. Unsere Techniker unterstützen Sie gerne.

Social Media

Wenn Sie über die Produktneuheiten und Aktivitäten von Kdesign auf dem Laufenden bleiben möchten, folgen Sie uns bitte auf LinkedIn.